Euro IV compliant Construction Machines featured at bauma China

The drive by the Chinese government and customers for ever more efficient low emission equipment is recognized by the presence of a number of Euro IV compliant machines on the Volvo Construction Equipment stand at bauma China.

To help China meet its targets for cleaner air through equipment with lower emissions, Volvo Construction Equipment (Volvo CE) will display two of its Euro IV compliant machines at this year’s bauma China in Shanghai: the EC220EL, a 22-ton crawler excavator, and the P7820DL ABG paver. When Euro V legislation comes into force on January 1st 2019, both these machines can meet the new emissions requirements with a simple software update.

EC220EL crawler excavator

Featuring Volvo’s latest D6 engine, the EC220EL’s fully optimized hydraulics system and ECO mode deliver the precise amount of power required to complete the task in hand. The auto engine shutdown feature helps further reduce fuel consumption and emissions by automatically switching off after the excavator has been inactive for a pre-set amount of time.

The excavator can be adjusted to take a wide variety of hydraulic lines, which are factory fitted with breaker and shear piping, as well as rotator piping. These provide the correct flow and pressure for special attachments such as mowers and grinders, shears, crushers and tilt rotators. A password-protected attachment management system pre-sets hydraulic flow for up to 20 different attachments.

The X-shape lower frame enables even weight distribution for increased stability and durability, and helps prevent damage from rock and debris. The heavy-duty undercarriage likewise creates excellent tractive force in demanding terrain. The robust design of the boom and arm includes internal plates positioned to support pressure points during a wide range of applications.

A comfortable operator is a productive operator, which is why the new Volvo EC220E places comfort at the heart of its design. All machine interfaces – including the joysticks, keypad and easy-to-read 8” LCD monitor – are ergonomically designed and can be fine-tuned according to operator preference. For the safety of both the operator and site staff, Volvo’s 22-ton model now also includes an optional side view camera in addition to the rear view camera to cover the visual blind spot.

P7820DL ABG paver

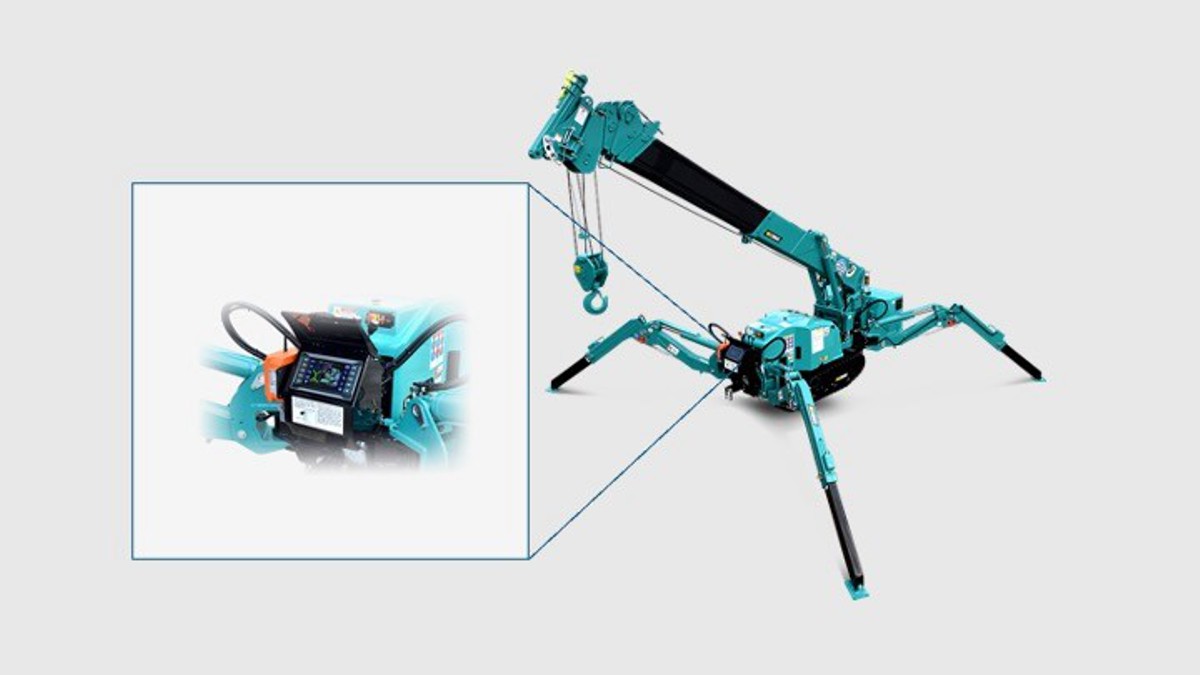

The Euro IV compliant P7820DL ABG paver, which has been developed specifically for the Chinese market, features the latest Electronic Paver Management system – EPM 3. It enhances machine control and optimizes the paver for specific applications. The system consolidates the control buttons, arranged in a bird’s-eye view layout, to guide the operator through individual working functions. Functions can be quickly selected and adjusted using the ergonomically-positioned control dial.

From the operator platform, operators have good visibility all around the paver, hopper, auger channel and screed – enabling the operator to check material supply and flow at a glance. The new glazed area on both sides of the platform provides even greater visibility, optimizing overall efficiency and jobsite safety. Even in low-light conditions, operators can pave with precision thanks to LED work light and balloon light choices.

Power to perform

Beyond machine control and operator comfort, the Volvo P7820DL ABG paver is packed with high quality features, starting with the Volvo engine. Two engine variants are available for emission regulation China III and future China IV readiness. Combining high torque and low RPM, both variants are specifically tuned to the hydraulic system for market leading power, productivity and fuel efficiency. The system features the adaptive ECO mode that matches the engine output to the jobsite requirement. This default function can reduce fuel usage by up to 30%, benefiting customers’ bottom line and the environment.

Whatever the weather or application, the P7820DL ABG paver can achieve a smooth, even mat surface, owing to the automatic track tensioning system and the extra-large hopper, which has been specifically extended by 300 mm for the Chinese market. This longer hopper gives extra-large trucks with bigger overhangs enough space to feed the paver

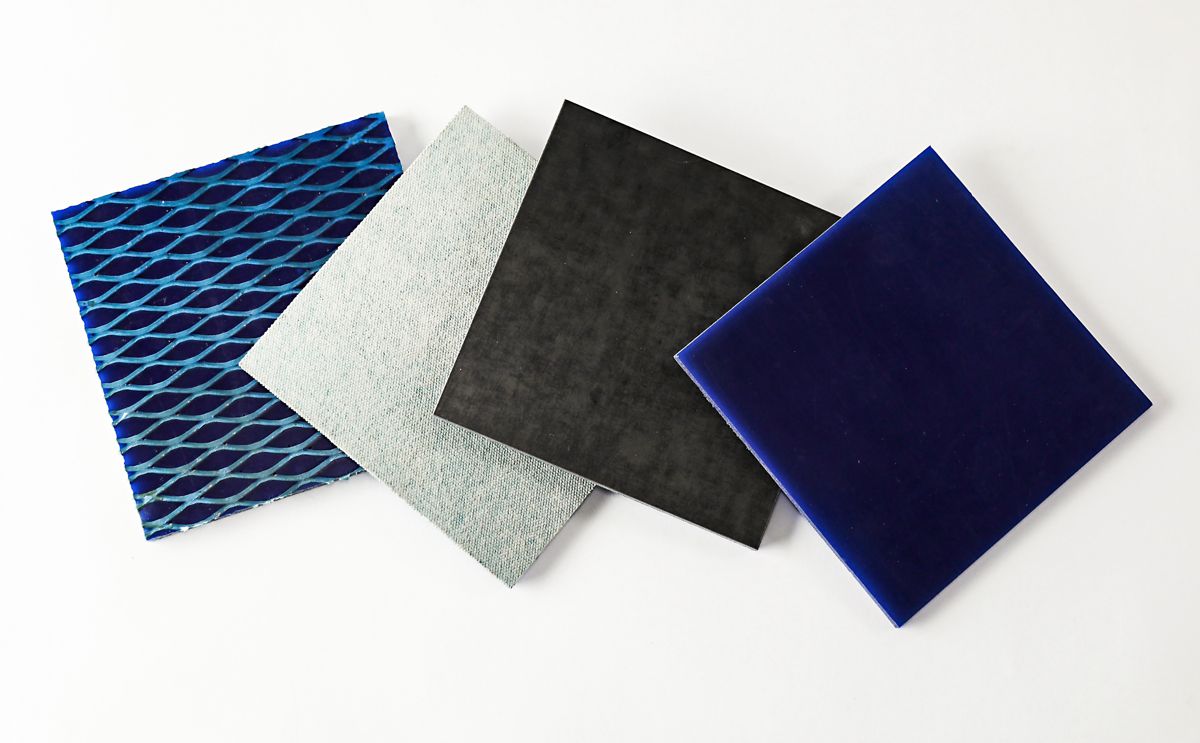

Industry-leading screeds

Volvo screeds are designed to provide premium pavement quality, uniformity and smoothness. Versatile and efficient in paving widths up to 11 meters, the Volvo P7820DL ABG paver features industry-leading screeds, capable of handling a wide range of materials.

Volvo’s tamper bars achieve material target density over the entire working width and are fully hardened for lasting durability. Depending on application and condition, Volvo customers can choose from the wide range of single or double tamper screeds to ensure a smooth surface. The Volvo ABG double tamper technology offers the highest degree of pre-compaction behind the screed, essential when paving thick asphalt and cement-treated base (CTB) material.

What’s more, the paving crew can meet various jobsite requirements by simply adding or removing screed extensions in minutes, with no special tools required, thanks to Volvo’s quick coupling system. Safety and quality are further enhanced by the new hydraulically-controlled end gates, delivering faster handling for the screed operator and a clean side finish.