Recycle with Metso sustainable solutions for metal and waste recycling at IFAT 2018

During IFAT 2018, the World’s Leading Trade Fair for Environmental Technologies, Metso experts will share the most recent insights on how customers can improve process efficiency, reliability and safety with industry-leading metal and waste recycling solutions.

Metso has been providing equipment and services for the recycling business for some 100 years. With thousands of installations worldwide, we’ve developed one of the industry’s most advanced range of solutions, including equipment and complete systems for handling virtually every type of waste and scrap metal. The comprehensive range of recycling products is supported by an extensive scope of services for waste and metal solutions.

Featured solutions for scrap processing

Metso N-series(TM) recycling equipment is suitable especially for smaller and mid-market operators. The solidly engineered products offer many of the same features and benefits as the Metso Lindemann(TM) line of shears and balers and are fully supported by Metso’s global engineering and service teams.

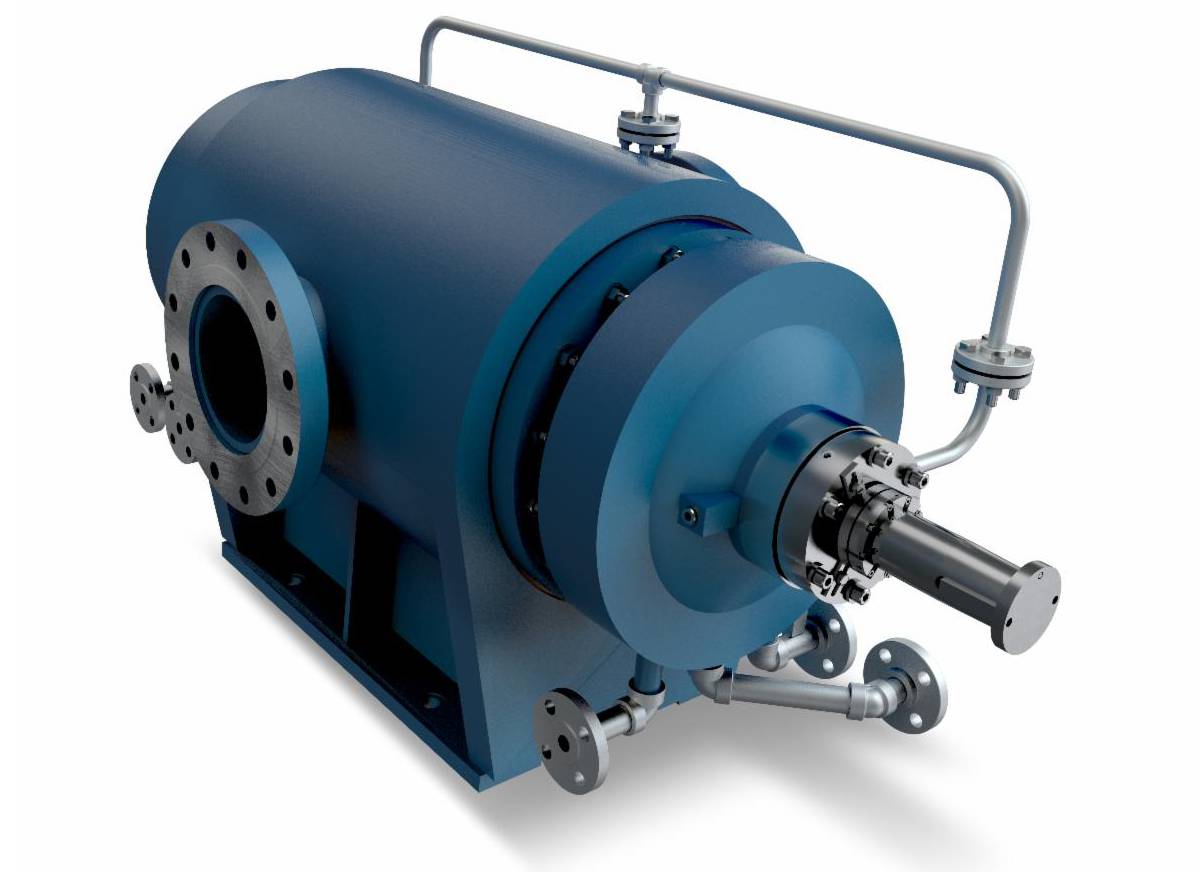

Metso Shredder Drive Assistant (Metso SDA) is a sensor based optimization tool that monitors and controls operating parameters of the scrap feeding process. It helps maximize the utilization of shredder power and boosts performance The system is available both as a retrofit solution and as an option for new machinery.

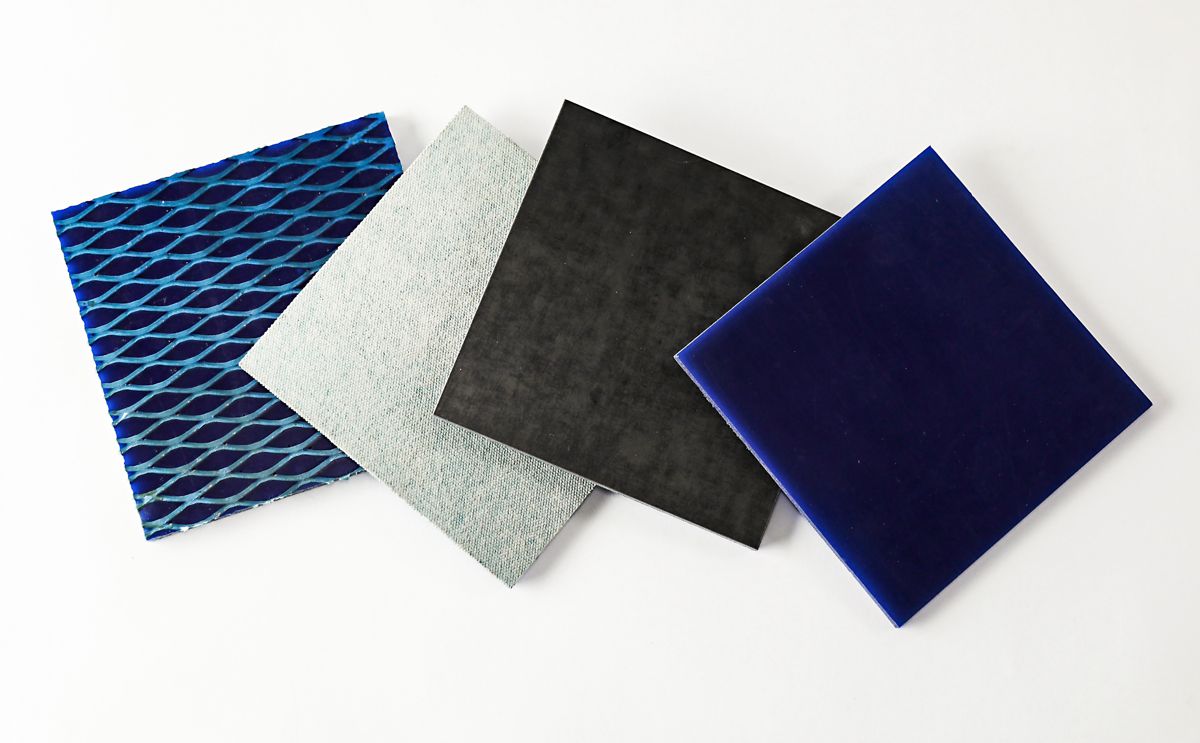

Metso’s Alloy Hammer is optimized for metal shredding and provides an excellent cost-per-ton shredding result. The special Metso alloy from the Group’s own foundry ensures substantially enhanced economic efficiency and is used with all Metso shredder series.

Outstanding waste shredder solutions for various customer needs

Metso’s M&J(TM) pre-shredding technology for stationary and mobile waste processing is based on powerful and tailored knife designs and open cutting tables. These distinct technical advantages benefit customers who are looking for a robust high-capacity shredder for continuous use at a high run rate even with hard and abrasive materials.

Metso’s M&J wide range of single and double shaft fine-shredders handle a wide range of different materials and deliver a highly consistent and homogenous output, thus making them extremely suitable for alternative fuel production (RDF/SRF).

Metso is also launching Metso Metrics for waste recycling, a digital solution to further optimize shredder capacity, efficiency and reliability. Through remote data monitoring, Metso Metrics gives customers near real time access to their shredder’s performance and operational status. Optionally, Metso’s expertise service can analyse the data and provide recommendations to further improve the shredders operation and reliability in the customers environment.

During the exhibition, Metso is interested in talking to recognized partners to join its global distributor network for its waste recycling solutions.

Meet Metso experts at IFAT 2018, booth 451/550 in hall B4, May 14-18, 2018.