HAMM celebrates more than 35 years of oscillation

Part 1: Tried and tested solutions for asphalt and earthwork

Over 35 years ago, HAMM became the first roller manufacturer to offer an oscillation drum for tandem rollers. In the meantime, this technology has become an integral part of the product programme. In the past five years alone, the specialists for compaction technology have delivered more than 3,000 machines with this particular technology. Today, one in five of the tandem rollers leaving the Tirschenreuth factory is equipped with an oscillation drum. One reason for this is the large variety of models, because with more than 35 models, HAMM has by far the widest offering of oscillation rollers in the world. In addition, only HAMM builds oscillation tandem rollers in the compact class as well as compactors for earthwork with oscillation compaction capability. And last but not least, the HAMM programme includes oscillation rollers for every market.

Successful pioneers

In the 1980s, HAMM undertook pioneering work in the development of oscillation compaction and was long the only supplier in the market. Customers were quick to appreciate the benefits of this technology. In the meantime, oscillation has proved itself and become successfully established in the market, as a result, most roller manufacturers have recently begun to offer this type of roller as well.

Fast, cost-effective and high-quality

The reason for this success is simple: oscillation rollers make for fast, cost-effective and high-quality dynamic compaction. In particular, tandem rollers with one oscillation drum and one vibrating drum achieve at least the same degree of compaction as double vibrating drum rollers, but with fewer passes. Added to this is the low vibration emission. This has made dynamic compaction on bridges, of thin layers and in sensitive areas (such as city centres, rail tracks, industrial plants) possible for the first time. In short: the scope of applications is enormous.

Compaction at every construction phase

Another bonus is that oscillation rollers can begin dynamic compaction directly behind the paver and then perform the main compaction. And even with lower asphalt temperatures at the end of compaction, oscillation ensures an increase in compaction without crushing the aggregate. Overall, when using oscillation rollers, the time available for compaction is significantly greater than with vibratory rollers.

Comprehensive portfolio for asphalt and earthwork

The HAMM portfolio encompasses tandem rollers for asphalt compaction ranging from 2.5 t to 15 t. When it comes to the pivot-steered rollers in the DV+ series, a popular choice for demanding road building projects, the share of oscillation rollers is particularly high: in 2016, around 40% of all DV+ series rollers were delivered with oscillation drums.

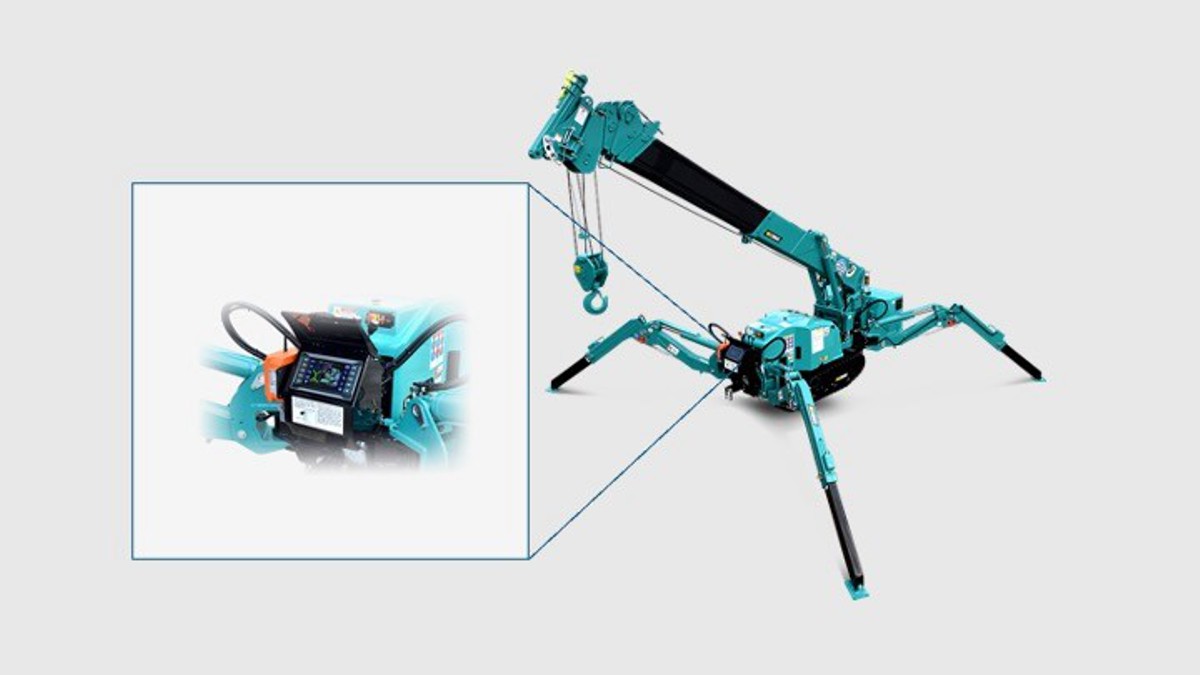

The oscillation rollers for the compact class from 2.5 to 4.5 t also experience great market demand. Hardly surprising, because HAMM is the world’s only manufacturer in this market segment. This also applies for earthwork. Customers worldwide seeking a solution for compactors with the facility to choose between oscillation and vibration find that only HAMM has the answer in the form of its VIO drums.

The oscillation principle

But what exactly happens in an oscillation drum, and how does oscillation differ from vibration? With vibration, a single unbalance shaft generates the upward and downward movement of the drum, causing it to strike the ground at a rapid rate. In oscillation drums, on the other hand, two unbalance shafts rotate synchronously, driven by a toothed belt. The unbalances are offset by 180° relative to one another. As a result, the drum performs a rapidly alternating forward/backward rotary movement.

Due to this movement, the drum directs the compaction force into the substrate tangentially to the front and rear in the form of shear forces. Here, unlike with vibrating drums, the compaction force acts continuously on the substrate because the drum is in contact with the ground at all times. This is why oscillation rollers compact dynamically as well as statically with their intrinsic weight the whole time.

Use for all layers

Oscillation rollers can be used to compact all earthwork and road building layers. They come into their own in earthwork, where re-loosening of the upper layers has to be effectively prevented, such as in garden and landscaping work. Another important application is the compaction of soils in vibration-sensitive areas, for example above gas, water and other pipework.

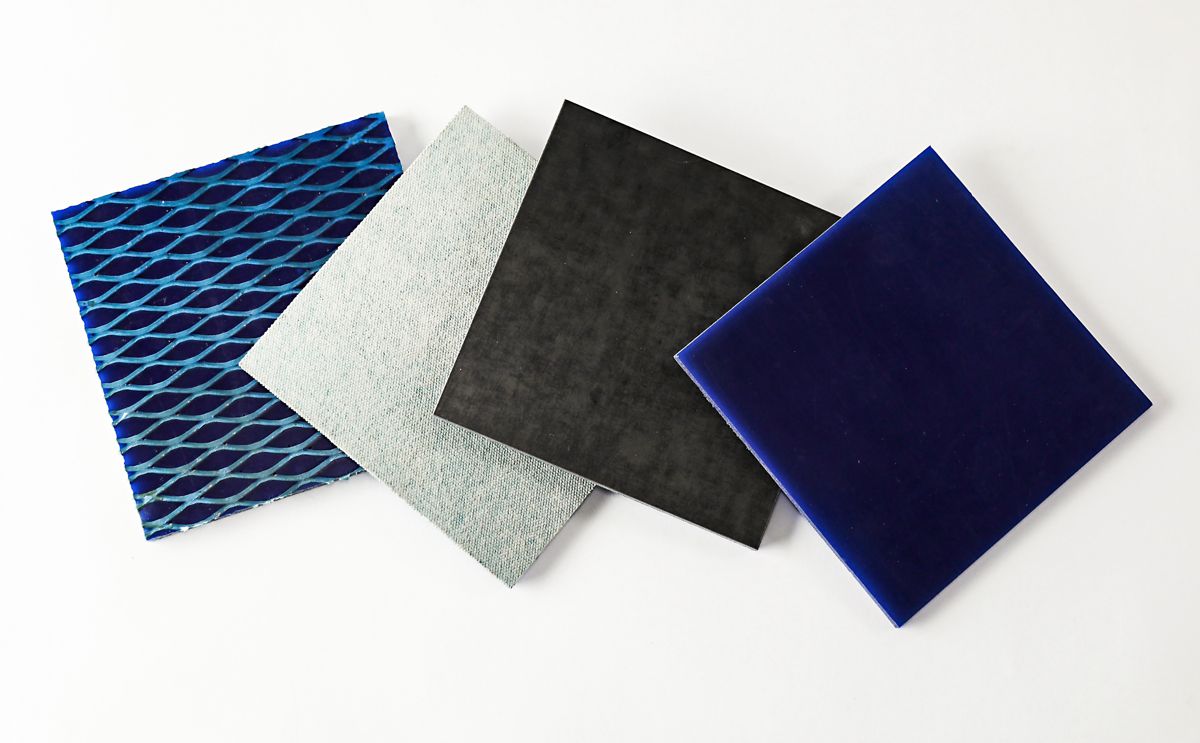

In asphalt construction, base courses, binder courses and surface courses can be reliably compacted with oscillation rollers. They perform especially well in the compaction of generally hard-to-compact asphalts such as SMA or in the case of polymer-modified material mixes. This is because, in contrast to vibration compaction, the effective direction of the vibrations during oscillation promotes the desired redistribution of long-chain binding agents.

Other applications include work on thin layers (surface courses, thin overlays), in vibration-sensitive areas (bridges, confined urban spaces, buildings or parking decks) and wherever the mix cools quickly (thin layers, windy or cold environments). Also of particular importance is joint compaction where the hot asphalt is to be compacted without damaging the adjoining cold asphalt.

Customers worldwide are moving to oscillation

As the examples show, dynamic compaction with oscillation has many intrinsic benefits and increases road construction quality. This is common knowledge among construction authorities and private customers alike. Last but not least, oscillation has also proved its worth in large projects. Here, the rapid increase in compaction makes for an optimised process with fewer passes. It is thus hardly surprising that the use of oscillation rollers is increasingly being specified for compaction when quality and longevity are paramount. An example of this is the construction of the F1 racetrack in Baku, where intermediate and heavy rollers were used. Another project involved remedial work in Vienna city centre in which compact rollers with oscillation were called for.