Kleemann introduces the MOBISCREEN EVO range of mobile screening plant

The MOBISCREEN EVO classifying screens supplement their tried-and-tested EVO series, whose screening and crushing plants are characterised by short tooling times, particularly good transport properties and high performance.

The track-mounted classifying screens of the MOBISCREEN MS EVO line are the latest Kleemann development which can be used in natural stone and recycling applications. The MS EVO line features two double-deck screening plants MS 702 EVO and MS 952 EVO as well as two three-deck screening plants MS 703 and MS 953 EVO. The screen area measures approx. 7 m² or 9.5 m² in the upper deck depending on the model.

As it is easy to transport, the screening plant is ideal for applications at alternating locations. Due to its short tooling times, it can be moved quickly and used flexibly. At the same time, the MS 952 EVO is very efficient and processes up to 500 tonnes of material per hour. With the MS 952 EVO up to three fraction sizes are produced, two of which are classified exactly.

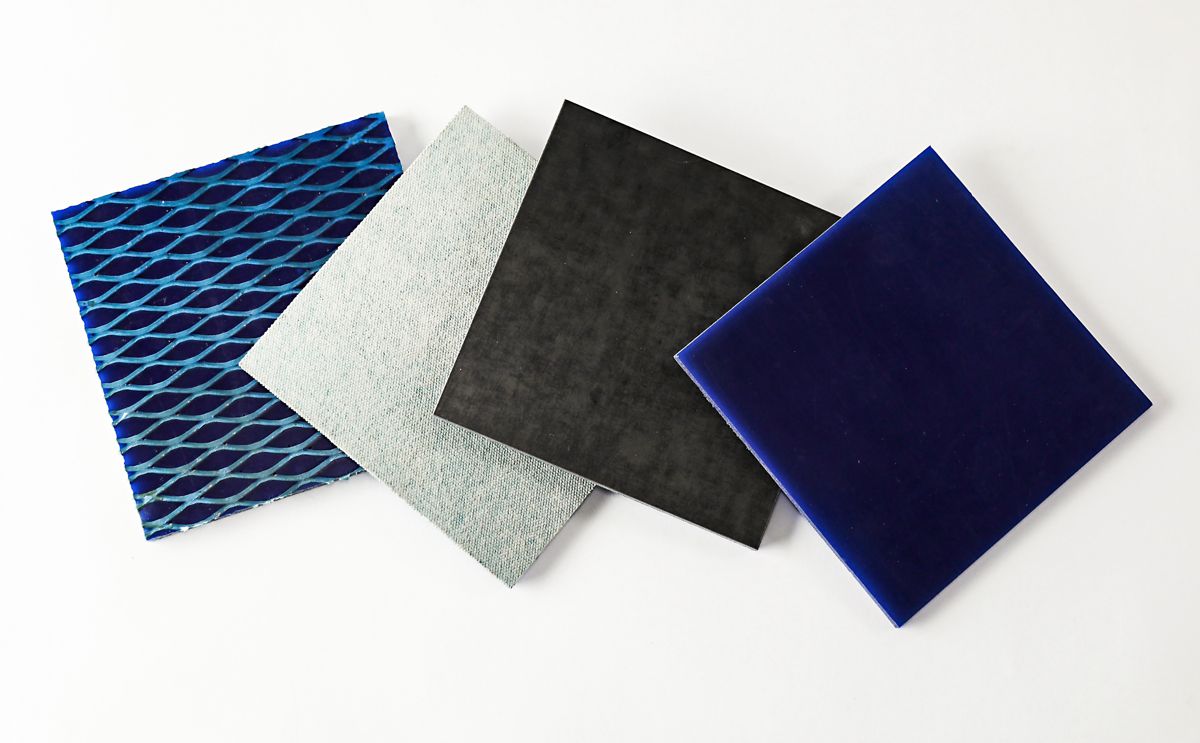

For further flexibility Kleemann offers a large number of different screen surfaces for different applications. The screen box is easily accessible from all sides, thus enabling the simple and quick replacement of screen surfaces. All other service components can be reached from the ground or the surrounding platform for uncomplicated maintenance work.

The MS 952 EVO can be fed by a wheel loader or an upstream crushing plant. The optimised material flow of the screening plant results in high efficiency. The feed hopper has a very large load capacity which opens in the direction of the material flow thus enabling an even material distribution. The material is conveyed further via the 1,200 mm wide feeding conveyor. As a result the incline of the belt can be adapted hydraulically to the material flow. The screening angle of the screen box can also be varied depending on the application.

The impact plate at the belt discharge distributes the material evenly on the screen area and thus protects the plant against wear. When interlinked with crushing plants from the EVO series, whose size and performance are compatible with the EVO screening plants, the plants work very efficiently. To increase work safety, Kleemann uses an emergency-off system that functions across all screening and crushing plants.

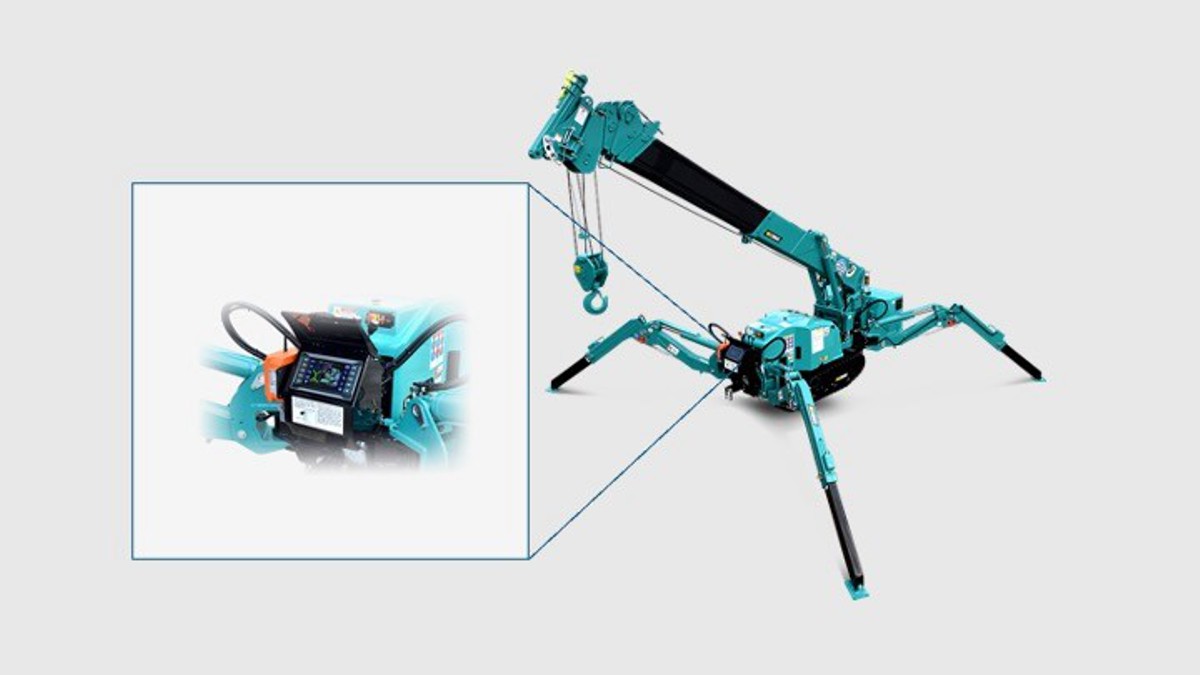

The plant is controlled via a user-friendly, mobile control panel which can be plugged in at three different points on the screening plant. All folding and lowering functions can be viewed, thus enhancing safety for the plant operator. The jerk-free movement of the MS 952 EVO is effected by means of proportionally controlled hydraulic valves. The automatic mode allows the plant operator to start up the machine within a few minutes. Production data and machine settings can be read off the control panel.

Kleemann GmbH is a member company of the Wirtgen Group, an expanding and international group of companies doing business in the construction equipment industry. This Group includes the five well-known brands, Wirtgen, Vögele, Hamm, Kleemann and Benninghoven with their headquarters in Germany and local production sites in Brazil, India and China. Worldwide customer support is provided by its 55 own sales and service companies.